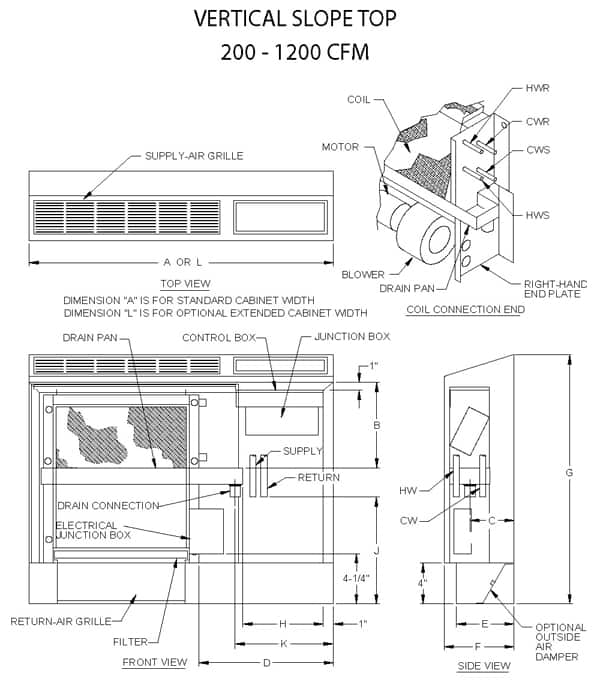

The Vertical Slope Top (F1-S) is a low-static (up to .25 ESP) fan coil is in a cabinet with sloping top and solid-side panels. Units may be mounted side by side for long corridor applications. The full sloping top discourages placement of books or other objects over the stamped louvered discharge grilles. The vertical upflow design is ideal for heating and cooling requirements in office buildings, college dormitories, churches, hospitals, hotels and motels. The F1-S fan coil comes with a coil, blower/motor assembly with quick-connect plug and a galvanized steel, powder-coated epoxy drain pan covered with ⅛-inch thick insulation. The galvanized steel cabinet is insulated with ½-inch thick, over three pound density, neoprene-coated fiberglass and finished in a soft-white powder-coat epoxy. The F1-S is intended for free-blow exposed wall mounting. The one-piece front panel is easily removed for complete service access. Filters are concealed from sight and easily removed without the need for tools.

Accessories Options

- Valve package controls – wide selection of factory-mounted valves and controls

- Outside air dampers/wall boxes

- Manual

- Motorized

- Bug screens

- Leveling legs

- TXV – factory-mounted

- Condensate float switch

- Condensate pumps

- Thermostats